Virtual Trainings (VTs) offered by the U.S. Department of Energy’s Better Plants program are the online version of the multi-day workshops known as In Plant trainings. As with the in-person INPLTs, the VTs will train the attendees to identify energy conservation and decarbonization opportunities, quantify savings from those opportunities, and implement projects to realize the cost savings.

These training workshops enhance the attendees’ understanding of working principles, knowledge of best practices, and capability of analyzing the energy performance of industrial energy systems. As of December 2024, DOE has hosted 31 virtual trainings with about 2,200 participants, and over $11M energy savings opportunities have been identified. The Better Plants team piloted a cohort of Virtual Trainings (VTs) at the end of 2020 as a means of continuing these interactive training workshops during the pandemic. Due to strong partner interest, DOE’s Better Plants program decided to offer VTs all year around for the same topics as are available in the in-person INPLTs. As of now, more than 1,200 people attended these VT sessions and over $9.2M energy savings opportunities have been identified.

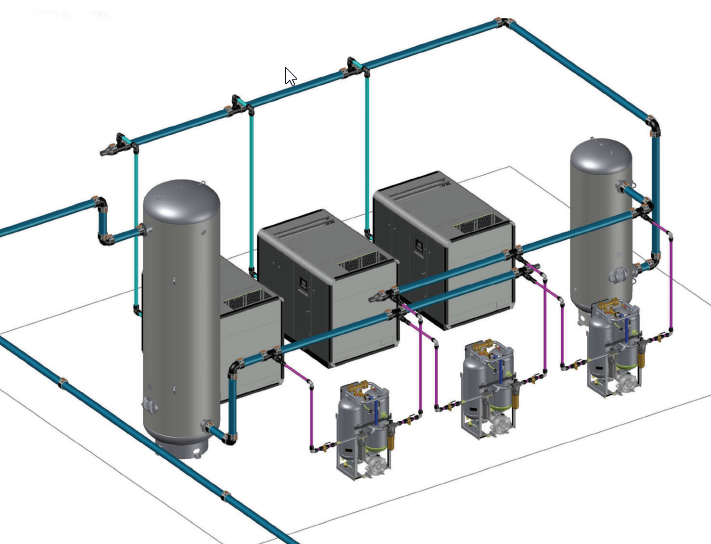

The Better Plants program will deliver a VT on Compressed Air Systems from Jan 24 to Mar 14, 2025. The Compressed Air VT will be performed by industrial experts and Technical Account Managers using online video communication technologies. The Compressed Air VT is comprised of 2.5-hour online training sessions (2-hours formal training and optional 0.5-hour Q&A) that will be delivered on every Friday 10:00 AM – 12:30 PM ET for eight (8) consecutive weeks. Participating in this VT is free and open to all the Better Plants program partners.

Participants will be trained on compressed air systems fundamentals and undertaking of a typical compressed air energy assessment, including virtual hands-on training on the DOE compressed air software tool. To maximize the benefits from attending VTs, homework assignments will be given to the participants at the end of each session and will be due by the next session. These homework assignments are designed to enhance participants’ understanding on the compressed air systems, as well as to identify and quantify energy savings opportunities. During the last session of the VT, participants are expected to create a summary presentation based on their assessment, present their findings, and share the scrubbed version with DOE.

At the completion of the VT, Professional Development Hours (PDHs) Certificates will be prepared for the attendees on a demand basis. Participants are expected to collect measurements/data from their own compressed air systems, perform an assessment, and identify energy efficiency opportunities with help from the instructors. To collect the assessment data, diagnostic equipment can be arranged and shipped to the partners. The Better Plants diagnostic equipment is available on a first come, first serve basis.

Jan 24 to Mar 14, 2025; Every Friday 10:00AM–12:30PM ET (2.0-hour formal training + optional 0.5-hour Q&A)

Week 1 – Compressed Air Systems Basics; Jan 24, 2025

Training experts introduce the rationale for system-specific in-plant trainings, describe the overall process of conducting a compressed air system assessment, provide an overview of the fundamentals of compressed air systems and fluid relationships, and describe the pre-screening process used during an assessment. Introduction to the MEASUR Tool

Week 2 – Compressor Types; Jan 31, 2025

Training experts will continue with an in-depth discussion on CAS assessment methodology. A discussion on the various types of compressors will be reviewed. Maintenance is discussed. How much heat does an air compressor generate? How to ventilate a compressor room.

Week 3 – Compressor Controls; Feb 7, 2025

Training experts will discuss different types of compressor capacity controls and how to efficiently match supply to demand. Positive Displacement and Dynamic controls. Review the pros and cons of pressure flow control valves. Demonstrate the CAS assessment module within DOE compressed air software tool.

Week 4 – Air Treatment; Feb 14, 2025

VT attendees will learn how misconceptions about air quality levels can affect compressed air system performance. Dryer types and Dew Point are discussed. VT attendees finalize their assessments within the DOE compressed air software tool.

Week 5 – Distribution System; Feb 21, 2025

Training experts and VT attendees review the correct method of pipe sizing and layout options. Discussions of velocity and how a pressure profile can be constructed from measurement data.

Week 6 – Demand Side; Feb 28, 2025

The experts present various methods of energy-saving measures and their applicability for the industrial compressed air systems equipment. Continue learning about the MEASUR Tool. What is an inappropriate use of air?

Week 7 – System Volume vs Storage; Mar 7, 2025

VT attendees focus on applications that consume a relatively high volume of air for short durations of time (sometime called “events”) and how to minimize them. A common solution to high volume, intermittent needs is compressed air storage. Learn the math behind calculating air storage.

Week 8 – Wrap-up Presentations; Mar 14, 2025

VT attendees present and discuss the results from their virtual CAS assessment. VT participants could invite their upper management to attend the wrap-up session. Once completed, VT attendees are given a Certification of Completion from US DOE.

Frank Moskowitz

Frank Moskowitz

Mr. Frank Mokowitz has an extensive background with over 40 years’ experience in plant engineering. He has a degree in mechanical engineering and education, including the refrigeration, electrical, plumbing trades. For the past 30 years, Frank has been an associate of Draw Professional Services primarily in the auditing, consulting, training and system design fields. His specialty consists of Compressed Air Systems (oil flooded and oil free), Vacuum Systems, Contaminate Removal, System Design and Energy Management.

Frank is a Compressed Air Challenge instructor for the Fundamentals and Advanced level of training, an AIRMaster+ instructor and a Department of Energy and CAGI expert on compressed air systems. Frank is also Vice-Chair for ASME Standard EA-4-2010 “Energy Assessment for Compressed Air Systems”; and is a member of International Standards Organization (ISO) technical committee for Air Compressors and compressed air systems energy management; TC118/SC6/WG4